Disinfectant products

PRAPAT is a manufacturer of general cleaning solutions and disinfectants under the trademark of “PEERAPAT”, namely multi-purpose cleaners, increasing the washing efficiency solution, etc. Furthermore, in order to expand customer groups to the food and beverage manufacturing industries, therefore the Company has established a subsidiary, Calvatis-Asia Pacific Company Limited (CVT), engaging in the business of importing machinery and equipment for sterilization systems installing in food and beverage manufacturing plants for supporting the distribution of disinfectants produced under the chemical formula and trademark of “Calgonit”. which is a brand of Calvatis GmbH (“Calvatis GmbH”) from Germany (a joint venture holding CVT shares in the proportion of 200% of the paid-up capital). Calvatis GmbH is an expert international disinfectant manufacturer with state-of-the-art technology and marketing networks in many countries around the world. CVT has a sufficiently experience and expertise in such products for more than 20 years. As a result, customers in the food and beverage manufacturing industries put their trust in CVT's products and services as well.

Food and beverage manufacturing factories must obtain “Good Manufacturing Practice: GMP”, which requires quality control of raw materials and hygiene throughout the entire production process. Therefore, cleanliness in the factory is extremely important. Food and beverages produced must be free from pathogens that affect consumers’ trust in the products. Disinfectants used for food and beverage industries must have special properties that are different from general disinfectant products which must contain a component of disinfectant and sanitizer.

CVT provides a full range of cleaning equipment installation services in food and beverage factories to support the distribution of disinfectants to such customers as follows:

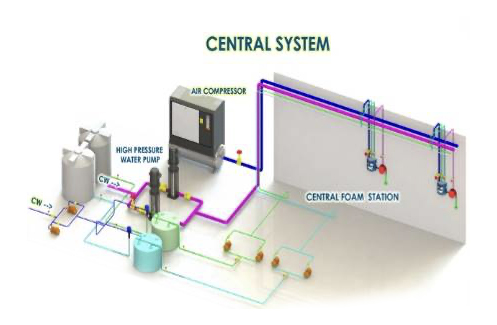

1. Central Foam SystemThe foam cleaning system is equipped with a control system and pump system for dispensing the cleaning solution into each production line. The liquid dispensed from the reagent tank will be conveyed to the foam box. When cleaning is required, the staff opens a valve to inject foam onto the surface of the equipment or production line conveyor. The advantage of the Central Foam system is that the staff can easily adjust the mixing ratio according to the desired formula, because the mixing tank is located outside the building or production line. |

|

|

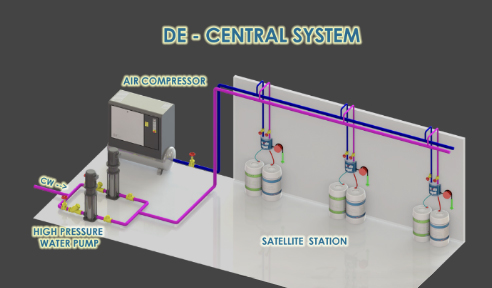

2. De-Central Foam SystemThis foam cleaning system is suitable for factories with different cleaning methods for each area of the plant. The mixing ratio is different for each application area where the storage tank is located inside the building or production line. |

3. Mobile Foam Device SystemPortable foam cleaner available in 20 liter and 50 liter sizes. The staff can move the equipment to clean the desired area with ease. This system is suitable for small factories. In addition, the Mobile Foam Device System is safe for users as it is not related to the electrical system. |

|

|

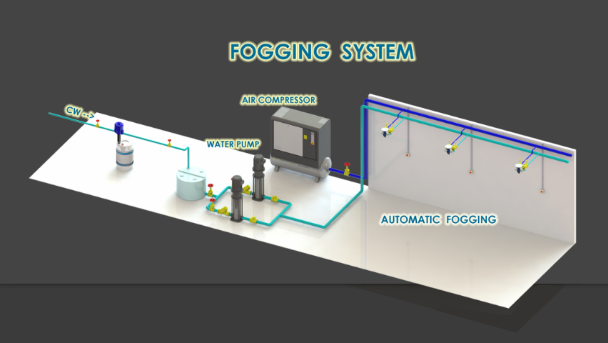

4. Fogging SystemThe automatic air disinfection system consisting of four-sided diffusing nozzles. It can spray 180 degrees. It will be used after cleaning the area and there are no people inside the area. The automatic air disinfection system sprays mist or fog from the ceiling to replace the air in the area to be cleaned for disinfection and deodorization. As a result, the area or room for food and beverage production clean and ready to start next production process. The air disinfection process takes about 3-8 hours at a time. |

5. Lubricant Conveyor SystemThe system will automatically spray the lubricant by spraying the lubricant onto the conveyor belt to prevent it from jamming and help disinfect. |

|